The eVSM Software is the easiest, most automated way to draw, analyze, and share value stream maps. It’s used to reduce waste, balance lines, save costs, increase capacity, and reduce lead times. Three standout aspects of the software. Draw value stream maps of any size in the shortest time possible with advanced features. Smart shapes and connectors, plus create, and many styling presets. Intuitive drag and drop interface with a contextual toolbar for effortless drawing. A complete library of professionally-designed value stream map symbols.

It is often said that a picture is worth a thousand words. The human brain processes images 60,000 times faster than text, and 90% of information transmitted to the brain is visual. Thus, humans respond to and process visual data better than any other type of data.

And when it comes to operational activities—like what you do at work, day in, day out—visualizing what exactly is going on has become a key capability.

Value stream mapping (VSM) is fast becoming one useful technique for visualizing delivery of products and services in order to identify opportunities for improvement. Let’s take a look.

What is VSM?

The ITIL® 4 Foundation publication defines a value stream as a series of steps an organization undertakes to create and deliver products and services to consumers.

Value stream maps are also one of the tools from Lean manufacturing. VSM visualizes the flow of a single product or service from supplier to customer, with the aim of identifying delays and processes that don’t add value.

The core principle of Lean manufacturing is the elimination of waste—any activity that does not add value from the customer’s perspective—in essence making the organization ‘lean’. The value stream map provides a basis for identifying unnecessary work (‘Muda’), particularly with regard to:

- Time

- Materials

- Processing activities

Lean thinking begins with one simple aspect: identifying value. This is the core objective of Lean management. But, without a clear picture of how you deliver value today, you can’t improve your value-creation process.

VSM provides that clarity for us by charting the flow of work through the different steps involved in the development/delivery of a product or service.

- Flow is ‘good’ when work moves steadily and predictably in relation to customer demand and supplier capacity.

- Flow is ‘bad’ when work starts and stops erratically and frequently.

By visualizing flow, VSM helps organizations move from bad to good through improvements in productivity and reduction in waste—leading to value creation for both you, as the supplier, and your customers.

(Learn about other mapping visualization approaches, like Wardley Value Chain Mapping, BPMN, and Business Capability Mapping, to improve company processes.)

Who uses VSM?

Best Value Stream Mapping Software

While VSM origins are in the manufacturing sector, the concepts apply to any product or service delivery framework, including:

- Logistics

- Government services

Basics of VSM notation

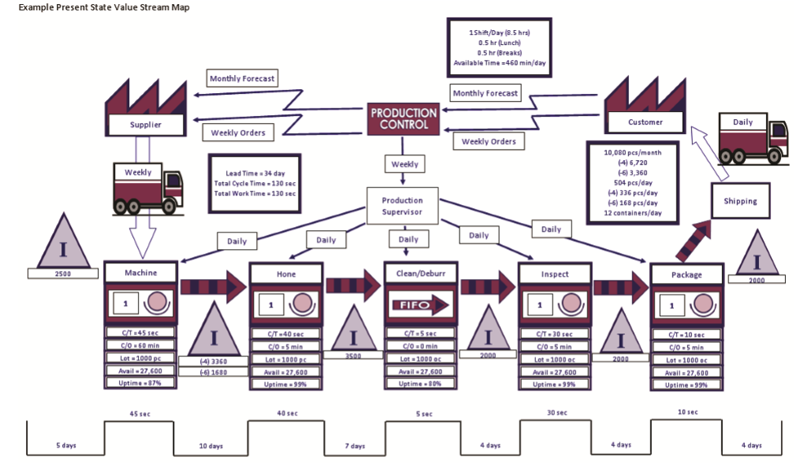

The below diagram is a basic example of a value stream map applied to a fast-food delivery restaurant:

Take a look at the diagram. You’ll see that a value stream map is a unique flow chart that uses special symbols to visualize flow of product materials. VSM breaks down the different steps and provides information related to that step based on:

- Time

- Quantity

- Quality

- Other relevant metrics

A basic overview of symbols used in VSM as defined in Lean include:

- Symbols representing customer and supplier, in the upper corners, look something like a warehouse.

- Symbols representing activities identify the main process steps, with a spot to indicate how many participants are needed. In our example, preparing food involves 3 participants, while the other steps require only 1 person.

- The data boxes represent information about the flow at each process step. In our example, we have included the following:

- Process time (PT): The time one product spends in a process step.

- Cycle time (CT): The time between two products coming out of the process step.

- Availability (A): The percentage uptime for the activity equipment.

- Two symbols represent flow direction. The thick, black-and-white arrows represent a push or move from one process step to another. The thin-line arrows represent information flow, both manual and electronic.

- The red triangles represent storedinventory, which includes any products/materials that are stopped and waiting for processing. This is different from products being worked on. The stored inventory can reveal wastes such as delays and overproduction.

- At the bottom, an up-down line represents the timeline.

- The upper step denotes useful processing time.

- The lower step indicates useless processing time, such as waiting and delays.

- The total times are summed at the end, to the right.

Creating a value stream map

It is clear that drawing value stream maps is a specialist skill. For some organizations, the basics might be enough. For more complex value streams there would be need for higher levels of knowledge.

- At the start, a whiteboard and markers might be enough to put together a decent value stream.

- Beyond that, mapping software might be required to manage icons and data.

- At the very top, the most complex, you would need automated tools that automatically collect and process data from the equipment being used.

Steps in mapping value streams

VSM brings together different stakeholders in the entire product creation/delivery lifecycle to perform two key tasks:

- Plot the current state.

- Identify an agreed future state where the lifecycle is optimized through the implementation of improvement initiatives that target reduction/elimination of delays and non-value adding activities.

Ideally the stakeholders should hold the exercise exactly at the point where the activities take place in order to get a first-hand view of the activities. (This is called ‘gemba’—the real place). They also need to have access to data that supports the different activities, with regard to timelines and inventory.

The steps involved in creating a value stream map can be summarized as follows:

Limitations of value stream mapping

For structured and standardized activities, VSM is perfect in identifying bottlenecks and sources of inefficiencies.

However, some activities are complex and heuristic in nature, requiring creativity, problem solving, and use of different elements at different times. These types of tasks are notoriously tricky to map.

VSM might not be the best tool for process activities where time, materials, and participants are highly variable. You might also struggle to map value streams when:

- You lack the knowledge required for mapping

- You don’t have the right configuration of automated systems to collect the related data.

- Your company culture has minimal knowledge sharing across functional siloes

In summary, it can be incredibly difficult to gain the kind of actionable insights an enterprise requires in order to make operational improvements.

VSM can help achieve significant visibility in product delivery activities, which supports value creation through the identification of improvement opportunities that enhance efficiency and effectiveness.

Related reading

- Data Visualization Guide, a series of examples and tutorials

Value stream mapping (sometimes called VSM) is a lean manufacturing technique to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Also known as 'material and information-flow mapping', it uses a system of standard symbols to depict various work streams and information flows. Items are mapped as adding value or not adding value from the customer’s standpoint, with the purpose of rooting out items that don’t add value.

Value stream mapping can be used to improve any process where there are repeatable steps – and especially when there are multiple handoffs. In manufacturing, handoffs are easier to visualize because they usually involve the handoff of a tangible deliverable through stations. If, for example, a problem arises when assembling a vehicle, line workers can see the physical parts accumulating and jamming up a certain part of the assembly line. They can then stop the line to solve that problem and get the process flowing again.

The application of value stream mapping – also referred to as “visualizing” or “mapping” a process – isn’t limited to the assembly line. Lean value stream mapping has gained momentum in knowledge work because it results in better team communication and more effective collaboration.

Much of the waste in knowledge work occurs in the handoffs (or wait time) between team members, not within the steps themselves. Inefficient handoffs lead to low productivity and poor quality. Value stream mapping helps identify waste and streamline the production process. Value stream mapping can be applied to both the product and customer delivery flows. Product flow focuses on steps required to optimize product delivery and completion. The customer flow focuses on the steps required to deliver on end user requests and expectations.

If you’re familiar with continuous delivery, then you likely already have an idea of how value stream mapping can apply to — and improve — that process. But before we dive into that topic, let’s take a look at some of the pros and cons of adopting value stream mapping.

The origins of value stream mapping are often attributed to Toyota Motor Corporation. However, this is a murky topic. Toyota may have adopted it from other origin sources or it may have grown organically from shared ideas in the lean manufacturing community. Early versions of diagrams revealing the flow of materials and information can be found as early as 1918 in a book called Installing Efficiency Methods, by Charles E. Knoeppel.

Inside Toyota the practice was called “material and information flow mapping” and was done almost as an afterthought. Toyota’s success and use of lean manufacturing practices helped promote value stream mapping as a modern best practice for high efficiency business teams during the 1990s.

Value stream mapping is critical for business sustainability. Here’s why:

- Reducing or eliminating waste can improve your company’s bottom line. As a bonus, you discover the root cause and the source of the waste.

- Once wasteful handoffs are identified as part of value stream visualizers, your teams can consciously improve behavior, culture, communication, and collaboration.

- Teams discard individual opinions and prioritize based on the customer’s perspective.

Value stream mapping can be wasteful in itself, if you are not careful. Here’s how you can avoid common pitfalls:

- The LOE (level of effort) to conduct value stream mapping should be balanced with the potential value and savings. Essentially, keep an eye on the return on investment ROI(return on investment) from the start.

- Involve experienced people from the business side and product side in conducting value stream mapping since the mapping process could be vastly cross-functional and complex.

- Fear and uncertainty are common symptoms when value stream mapping is conducted, and so the process of identifying waste can be intense.

- Improving a step here and a step there will rake in savings for sure. However, it may not directly translate to a bottom line improvement until a full walkthrough is completed. Having said that, baby steps are often a great way to start.

- Don’t rush to use professional charts, tools, and symbols right away. First, sketch with a pencil or use a whiteboard to outline the idea. Once the dust settles, formalize the map appropriately. Remember, you are trying to cut waste and not create any more than you already have.

Overall, doing value stream mapping is fine, yet overdoing it can be problematic.

Let’s briefly look at how value stream mapping can bring value to various industries. The domain determines the process items that flow through the value stream map.

In a supply chain, value stream mapping can root out costly delays leading to a finished product. In manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. The process items that flow through the value stream are materials.

In service industries, value stream mapping facilitates effective and timely services for external customers, whereas inside administration and offices, it facilitates services for internal customers. In healthcare, value stream mapping ensures that patients are effectively treated with high-quality care. The process items that flow through the value stream are customer needs.

How value stream mapping identifies and reduces waste

Value stream mapping originated in the enterprise manufacturing industry. As an example, let’s imagine an automobile factory receives orders for new cars and needs raw materials to produce them. The company uses value stream mapping to outline the steps required to produce a new car.

After reviewing car production steps, the company identifies a handoff stage in the development that appears wasteful. This handoff stage requires a forklift to move raw materials from one side of a warehouse to the production line. However, this move has safety risks and is time consuming. From this insight the company decides to permanently move the raw material storage directly adjacent to the production line. This increases efficiency and potentially removes the requirement of the forklift altogether!

Lean manufacturing has a set of seven types of waste generation.

Overproduction is a catalyst to many other forms of waste. When a manufactured product is overproduced it leads to further waste through unnecessary costs like extra storage, wasted raw materials, and capital frozen in useless inventory.

Inventory waste is the liability cost that comes with storing and preserving a surplus inventory. This waste includes waste of space for housing inventory, waste of rent for storage space, waste of transportation costs, waste caused from deterioration of housed products.

Motion waste is the cost of all the motion by person or machine that could be minimized. The previous example we demonstrated with the forklift and supply location is a great example of motion waste and optimization. Motion waste has many wasteful byproducts, including pollution, fuel waste from operating vehicles, maintenance repairs, and costs from equipment breaking down.

Accidents do happen, and they can be expensive. Defect waste management is the effort to identify and mitigate accidents and imperfections that lead to defective final products. Defects are costly as they need to be replaced, may have additional recycling costs, or may be a total loss of raw materials.

Over-processing waste refers to any step of the manufacturing component that can be deemed unnecessary. Examples include adding features users did not ask for Or polishing areas of a product that may not be visible to a user.

Waiting waste is the cost of any step in the manufacturing processing that is slow and causes a delayed reaction to the final output. Waiting causes expenses in lighting, heating, cooling, and the risk of materials, or contracts expiring.

Transport waste is very similar to motion waste. Transport waste deals with external transport movement between multiple locations or third-party partnerships where motion deals with internal movement in the same location.

A software development organization doesn’t deal with physically moving raw materials around warehouses to build a finished product. Software development entails shipping ideas into tangible user experiences that provide value to the customer.

Value stream mapping for a software enterprise looks at the flow of taking “idea input” from sources like customer support, sales requirements, competitor analysis and delivering that as valuable output to the end customer. The software development value stream mapping flow stages are primarily concerned with cross-team communication.

The user requests a feature, product teams design functionality, engineers receive the design and build the software, and the software is shipped to the end user. Value stream management for software can be used to identify points of waste between these stages.

The following is a list of seven types of waste found in software development or other creative work.

This occurs when software is pushed out in an incomplete state. It may happen due to a lack of complete specification, or lack of automated test coverage. Partially completed work also causes a cascade of other waste since additional work is needed to push more updates and fill in the missing functionality.

Often referred to as “feature creep”, extra features cause waste by doing more work than is required. Extra features are features directly not requested by users but cooked up internally on a hunch or speculation. Extra features may present themselves as well intentioned but often are a byproduct of a disconnect from actual customer needs.

Relearning waste can also occur from lack of internal documentation. If a software failure or outage occurs it is a best practice to investigate and document why the outage happened and how it was remedied. If a failure occurs again and it has not been documented, there will need to be another investigation and remediation.

Relearning waste also occurs when a team or individual needs to overcome the learning curve of an unfamiliar technology. Tech trends rapidly come and go. Flavor of the month frameworks and libraries get jumped on by junior developers pumped by market trends and hype. Even though an organization already knows how to build a certain feature they may have to relearn how to build it in new framework.

Handoff waste occurs when project owners change when roles change or there is employee turnover. Key team members leave and a project gets handed to a team member without context. This scenario is hard to avoid. Handoff otherwise occurs from poor management and changing team member priorities while in action.

Handoff waste can also occur through communication pipelines. For example, in a DevOps team, the development team can integrate more closely with the operations team to help prevent any communication errors when passing off a product to be maintained. This is an example of avoiding handoff waste.

Delays usually occur when there are tightly coupled dependencies on a project Downstream execution on a project may be halted due to a dependency on an upstream decision or resource. While it's best to avoid dependencies between these tasks, it can be challenging to perfectly decouple tasks. A delay in one task may cost delays in dependants. Delays can cause a cascade of waste. Software development often happens at a rapid pace and tasks are distributed amongst team members.

Task switching waste has similar qualities as handoff waste. Where handoff waste occurs when tasks switch owners between team members, task switching waste happens to an individual. Mental context switching is expensive. There is a mental cadence or “flow” that software engineers achieve to optimally produce good code. Efficient organizations work to optimize this mental state for their engineers. Inefficient organizations bombard their engineers with non-critical distractions like meetings and emails that disrupt their workflow.

Defect waste happens when bugs are pushed in software. Defects are similar to partially completed work but can be more wasteful because defects are unknown and partially completed work is usually known ahead of time. Defects may be identified by customers and then reported to customer support, which can be an expensive pipeline that causes delays and task switching.

There are standard symbols for outlining value stream mapping.

How to create a value stream map - one step at a time

What problem are you solving from the customer’s standpoint? Do your customers feel like it takes too long to deliver new features or improvements to a product? Publish the problem statement and get everyone on the same page.

Empower a mature and experienced team who can skillfully address these problems in a timely fashion. The C-suite should set aside enough budget to ensure that execution is uninterrupted.

Once the problem statement is published, limit the scope of your value stream mapping accordingly. You may not need to map the release process in its entirety, and focus on a particular area instead.

Be sure to review the bounded process. This can make a difference, since firsthand experience cannot be substituted by (possibly biased) narratives and (possibly incomplete and inaccurate) documentation done by others.

Define the steps. I conduct a value stream mapping analysis multiple times. While this may sound redundant, I have found missing pieces in the second pass that were not exposed in the first pass. And when we investigated further, skeletons fell out of the closet during the third (and final) pass!

As you conduct value stream mapping, note the process data in the data boxes of the map. Process data includes (but is not limited to) the number of people involved, the average number of working hours, cycle time, wait time, uptime, downtime, and more.

Map out process times and lead times.

Be inquisitive. Do your teams have multiple dependencies with each other? Is your lead time too long? If it is, is it because your test suites don’t (or can’t) run in parallel? Do you have stable environments, or do you observe intermittent test failures that the teams cannot reproduce?

Or, you may have process steps that you think are valuable but don’t mean anything to the customer. Regarding the information flow, look for stagnation and drag in the flow. Note whether it was a push versus a pull.

You may not be able to nail a full and final version, and that’s okay. Make sure your new map aligns with the company’s vision.

Also, nothing is set in stone. Based on customer needs, make continuous adjustments.

Value Stream Mapping Software Free For Mac

Follow the value stream mapping of the future and validate that it makes better sense for the customers. It should have solved the problem statement that you started with. Monitor KPIs regularly and learn from trends. Make sure everyone is rowing in the direction of customers.

If you're interested to see what the finished product looks like, here's a value stream map example.

Value Stream Mapping Software Visio

The application of value stream mapping to continuous delivery

In software development, value stream management can reveal inefficiencies from idea to production, including feedback loops and rework. It can help reduce the number of steps and the need for rework. Mapping your process can help you visualize where handoffs occur so you can also discover where wait time keeps work from moving through your system.

Value Stream Mapping Software Open Source

By definition, continuous delivery (CD) doesn’t need to make use of value stream mapping and it is perfectly possible to design and implement a CD pipeline without knowledge of value stream mapping.

With proper implementation, value stream mapping fosters a culture of continuous improvement that has been proven effective in software engineering and operations. The map illustrates the outcomes of the value stream analysis, providing a visual tool to facilitate understanding and communication.

Value stream mapping can be applied to industries that are looking to improve their processes across all business functions. Visualizing handoffs help optimize the flow and help generate savings. Without the visualization, expect your meetings to run longer and business outcomes to be hazy.

Value stream maps can do wonders to fuel continuous improvement. In the software development world, continuous improvement is at the heart of the continuous paradigm where continuous delivery pipelines deliver products frequently, predictably, and sustainably to customers. When you can release at the speed of ideation, your customers will be happy!

Value stream mapping also helps improve team culture, since productive teams are more engaged and are fun to work with! Since culture, productivity, and savings are just some of the rich dividends, shouldn’t value stream mapping be near the top of your single prioritized backlog?